Products

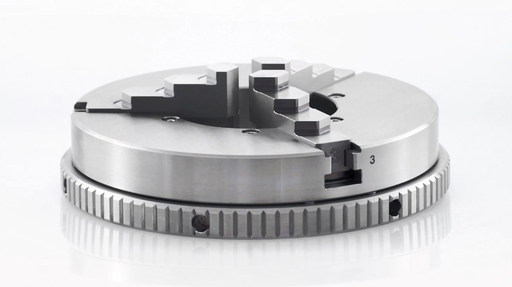

Precision clamping chucks

Applications

Koch stainless steel chucks are especially suitable for applications where low clamping forces, but high precision and small size are required:

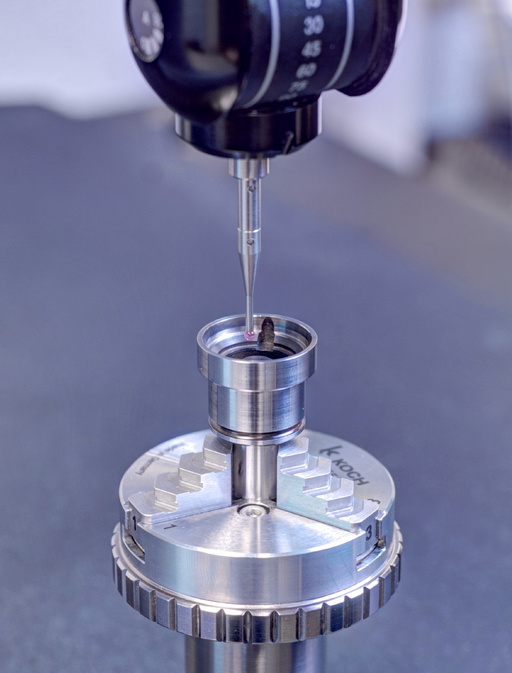

metrology

measurement of gearbox shafts

measurement of spindles

testing of needles and cannulas

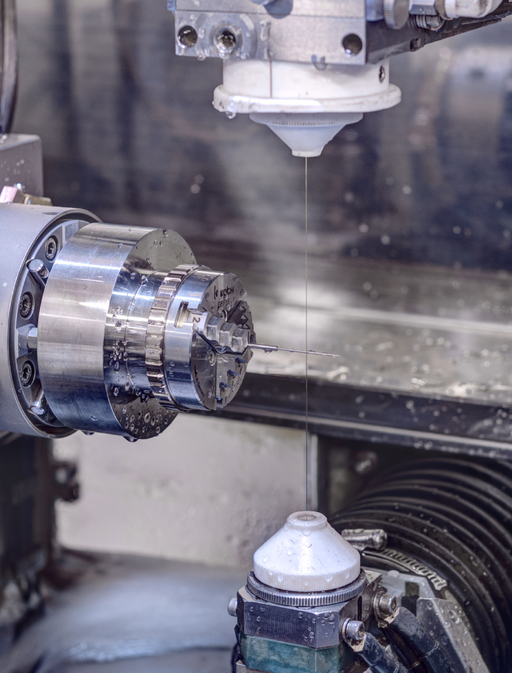

electrical discharge machining

wire erosion with rotating spindle

usage as work piece holder in dividing machines

underwater applications

ultrasonic testing

ultrasound cleaning

laser applications

laser marking

laser welding

All stainless steel manual chucks are suitable for vacuum and underwater use and can be supplied with special greases for these applications on request.

Benefits

Koch stainless steel chucks offer many advantages over normal chucks:

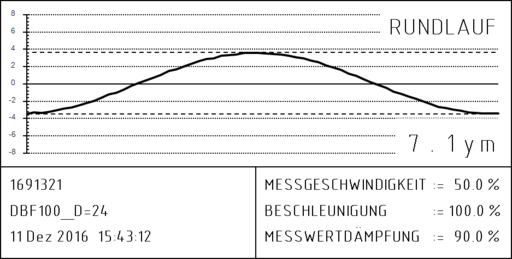

Superior precision

All chucks in the DBF series have excellent concentricity (guaranteed: ≤20µm, typical ≈10µm) and a high clamping repeatability (5µm).

small size

Koch chucks are much smaller than other chucks with comparable clamping range.

100% stainless

All chucks are completely made of stainless materials. The chucks therefore do not require any corrosion protection and can also be used under water.

Simple assembly / disassembly

The chucks of the DBF series consist of few components and are accordingly quick to disassemble and assemble.

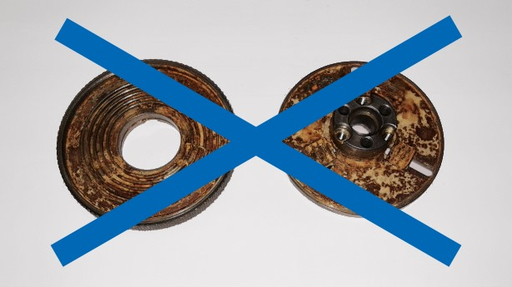

Easy disassembly / assembly of DBF63 (mounted on an adaptor for a Hirschmann zero-point clamping system

No tools required

All chucks of the DBF series can be conveniently adjusted by hand by turning the clamping ring. No key or similar tools are required.