Services

Manufacturing

CNC turning

We ensure that individual parts are manufactured cost-effectively by using cycle-controlled lathes. These allow us to machine items made of any material and with diameters from 1 to 350 millimetres.

CNC lathes with powered tools and a Y-axis are available to manufacture larger quantities. Machines with a Y-axis have the great advantage of making milling much easier and more extensive with powered tools. Even purely milled parts can be manufactured more quickly from the bar than by CNC milling. The production program therefore ranges from individual parts and small quantities through to extensive batch sizes.![]()

| lathe list: |

|---|

| CNC lathe Gildemeister Graziano GT 300 GY with powered tools, Y-axis, counter spindle and short bar feeder (from bar to Ø 50 mm, in the chuck Ø approx. 160 mm, centre distance 300 mm) |

| CNC lathe Gildemeister GTX 320 V4 linear with powered tools and Y-axis (from bar to Ø 60 mm, chuck diameter 210 mm, centre distance 450 mm) |

| CNC lathe Gildemeister CTX 410 V4 with powered tools and Y-axis (from bar to Ø 65 mm, chuck Ø 200 mm, centre distance 600 mm) |

| CNC lathe Daewoo Puma 200 LMA with powered tools (from bar to Ø 42 mm, in the chuck Ø approx. 265 mm, centre distance 550 mm) |

| 2 lathes with automated cycles Weiler E 35 (centre distance 950 mm) |

| Lathe with automated cycles Weiler E 60 (centre distance 1000 mm, swing diameter over bed 650 mm, swing diameter over sliding tool 400 mm) |

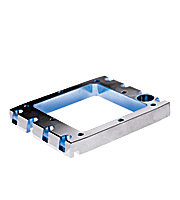

Aluminium work-piece carrier, chemically nickel-plated