Services

Manufacturing

Other processes

Apart from broaching slot widths up to 12 mm, our company's service range also includes wet barrel finishing with modern barrel finishing vibrators. This is where work pieces vibrate together with special ceramic or synthetic resin grinding bodies. This process is especially suited for rounding off edges for example. Stainless steel and other materials are specifically kept separate from each other during processing.

Glass bead blasting and laser-marking extends our offered services.

Cooperation with select and reliable partners means that we can offer the latest technology as well as all the usual surface and heat treatment processes.

This includes:

- Welding (including laser and electron beam welding)

- All hardening processes

- Burnishing

- Powder coating

- Anodizing

- Chemical nickel plating

- Galvanising

- Plasma polishing etc.

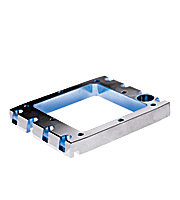

Aluminium work-piece carrier, chemically nickel-plated